With the development of the security industry, security products are constantly updated, new products and technologies are frequently introduced, and security cable manufacturers are increasing. However, the threshold for the security cable market is relatively low, and the phenomenon of counterfeit and shoddy caused by cutting corners is widespread. Cables are used as basic construction products. Most of the production and inspection of products are fixed equipment, and their technical content is not high. Some people in the industry said that the current state does not have much restrictions on individual factory openings, which has led to the existence of a large number of domestic workshop-type cable factories. Some manufacturers have not been registered, and there are no relevant product test certificates and quality inspection reports. The products are sold at low prices in various markets in the world, and the reliability of product quality and performance cannot be guaranteed. These have brought great losses to the engineering companies and users. At the same time, due to the increase in the price of raw materials, in order to reduce costs, some bad manufacturers even use copper-clad aluminum, recycled copper and other materials instead of oxygen-free copper.

The quality of the cable is identified, and real testing requires specialized equipment and instruments. In engineering practice, the following methods can be used for preliminary identification:

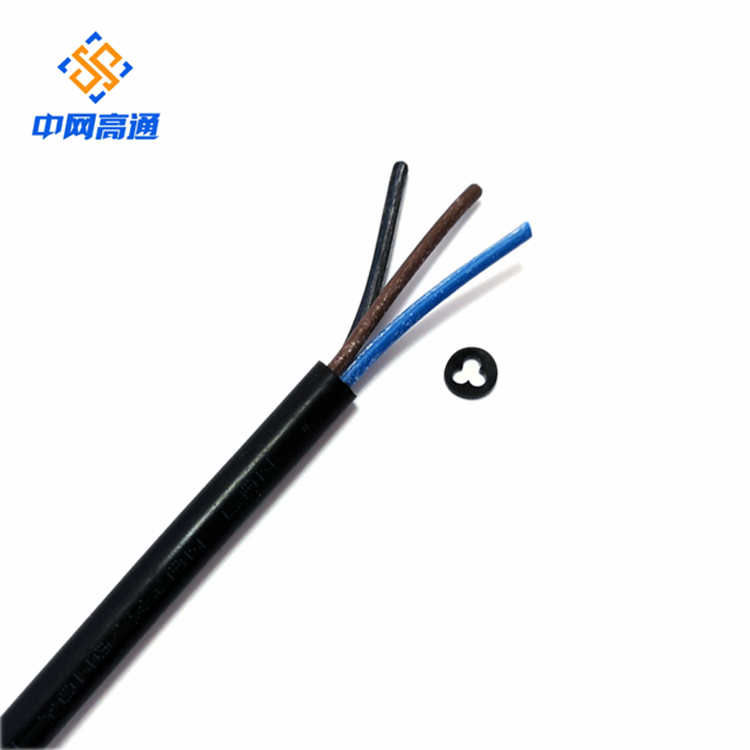

1. PVC sheath: The regular "unevenness" of the braided net can be seen on the surface, indicating that the processing technology is good, and it will not cause relative sliding, which is a good cable. "Roughness", pinching the sheath with your hands has a loose feeling, which is a poor cable.

2. Check the shielding wire netting: whether the number is sufficient, copper wire netting, check solderability, tinned copper wire is scratched to see if it is copper wire, the hardness of the aluminum-magnesium alloy wire is significantly greater than that of copper wire; Uneven distribution, not tightly wrapped with insulation, etc. are poor cables.

3, check the core wire: diameter ------ SYV cable is 0.78 to 0.8mm, SYWV cable is 1.0mm; recently there is a SYV75-5 core wire with a diameter of 1.0mm, the characteristic impedance of this cable is definitely not 75 ohms, should not be used in 75 ohm transmission systems.

4. Check the adhesion between the core wire and the insulation layer: Cut the insulation layer obliquely, and pull the core wire in the direction of peeling to see if the core wire and insulation layer are bonded with craft materials; a good cable has a large adhesion and a poor cable No sticking. Longitudinal tensile test: Take a one-meter cable, peel off the core wire layer by layer, insulation layer, shielding layer, and outer sheath, leaving 10 cm long each. The method is: hold the two adjacent layers of the cable with two hands and pull them in opposite directions; a good cable cannot be pulled with general strength, and a poor cable can be easily pulled out without much effort.

The main points of the above security cable identification are mainly visual appearance identification. For more in-depth identification, certain tools or equipment testing are needed. For example, transmission performance testing and oscilloscope measurement can be used to identify.